Understanding the Importance of Diesel Solenoid Valves in Diesel Engines

In the world of diesel engines, one component that often gets overshadowed by larger parts is the diesel solenoid valve. This tiny yet powerful device plays a crucial role in the efficient functioning of diesel engines. Whether you are a seasoned mechanic, a diesel engine enthusiast, or a business owner looking to optimize your machinery, understanding the functionality and significance of solenoid valves can enhance your operation dramatically.

What is a Diesel Solenoid Valve?

A diesel solenoid valve is an electromechanical device that controls the flow of diesel fuel in an engine. Typically, it consists of a coil, a plunger, and a spring. The core function of the solenoid valve is to serve as an on/off switch, allowing or preventing fuel from passing through, depending on the needs of the engine at any given time.

How Does a Diesel Solenoid Valve Work?

The operation of a diesel solenoid valve is straightforward yet ingenious. When electricity runs through the solenoid coil, it generates a magnetic field that attracts the plunger towards it. This action opens or closes the pathway for diesel fuel, thus regulating its flow into the engine. The precise control over fuel flow ensures that the engine can perform optimally under a variety of conditions, thereby enhancing power and fuel efficiency.

Types of Diesel Solenoid Valves

Understanding the different types of diesel solenoid valves is essential for selecting the right component for your diesel engine. Here are the main types:

- Direct Acting Solenoid Valves: These are triggered directly by the solenoid coil with minimal pressure loss and are ideal for small applications.

- Pilot Operated Solenoid Valves: These are used in larger applications, where a small solenoid valve controls a larger flow of diesel through a secondary mechanism.

- Two-Way Solenoid Valves: These valves can either allow flow or block it, functioning as a basic on/off switch for fuel.

- Three-Way Solenoid Valves: These are more complex and can direct flow between two sources or return fluid to a reservoir.

Importance of Diesel Solenoid Valves in Diesel Engines

The significance of diesel solenoid valves in diesel engines cannot be overstated. Here are several reasons why they are essential:

1. Enhanced Engine Performance

By precisely controlling the flow of fuel, diesel solenoid valves help maintain optimal engine performance. This control mechanism ensures that the engine receives the correct amount of fuel as needed, which can improve acceleration and overall efficiency.

2. Fuel Efficiency

Efficient fuel flow regulation leads to reduced fuel consumption. This is particularly beneficial for businesses that rely on diesel engines for heavy machinery, as it can translate to significant cost savings.

3. Reduced Emissions

With stricter regulations around emissions, it’s essential for diesel engines to minimize pollutants. Optimized fuel flow through solenoid valves allows for more complete combustion, leading to lower emissions and a reduced environmental impact.

4. System Protection

Incorporating high-quality diesel solenoid valves in your engine design can help protect against issues like cavitation or over-pressurization, ultimately extending the lifespan of the engine and its components.

Common Issues with Diesel Solenoid Valves

Like any component, diesel solenoid valves may encounter issues that can affect engine performance. Understanding these issues can help in early diagnosis and maintenance. Common problems include:

- Electrical Failures: Since solenoid valves operate on electricity, issues such as blown fuses or poor wiring can halt their functioning.

- Blockages: Dirt and debris can clog the valve, preventing it from opening or closing completely.

- Mechanical Wear and Tear: Over time, components within the solenoid may wear down, leading to potential failures.

- Heat Damage: Excessive heat from engine components can damage the solenoid, creating resistance or failure in function.

How to Maintain Diesel Solenoid Valves

Proper maintenance of diesel solenoid valves is vital to ensure they perform efficiently and have a long operational lifespan. Here are a few maintenance tips:

Regular Inspections

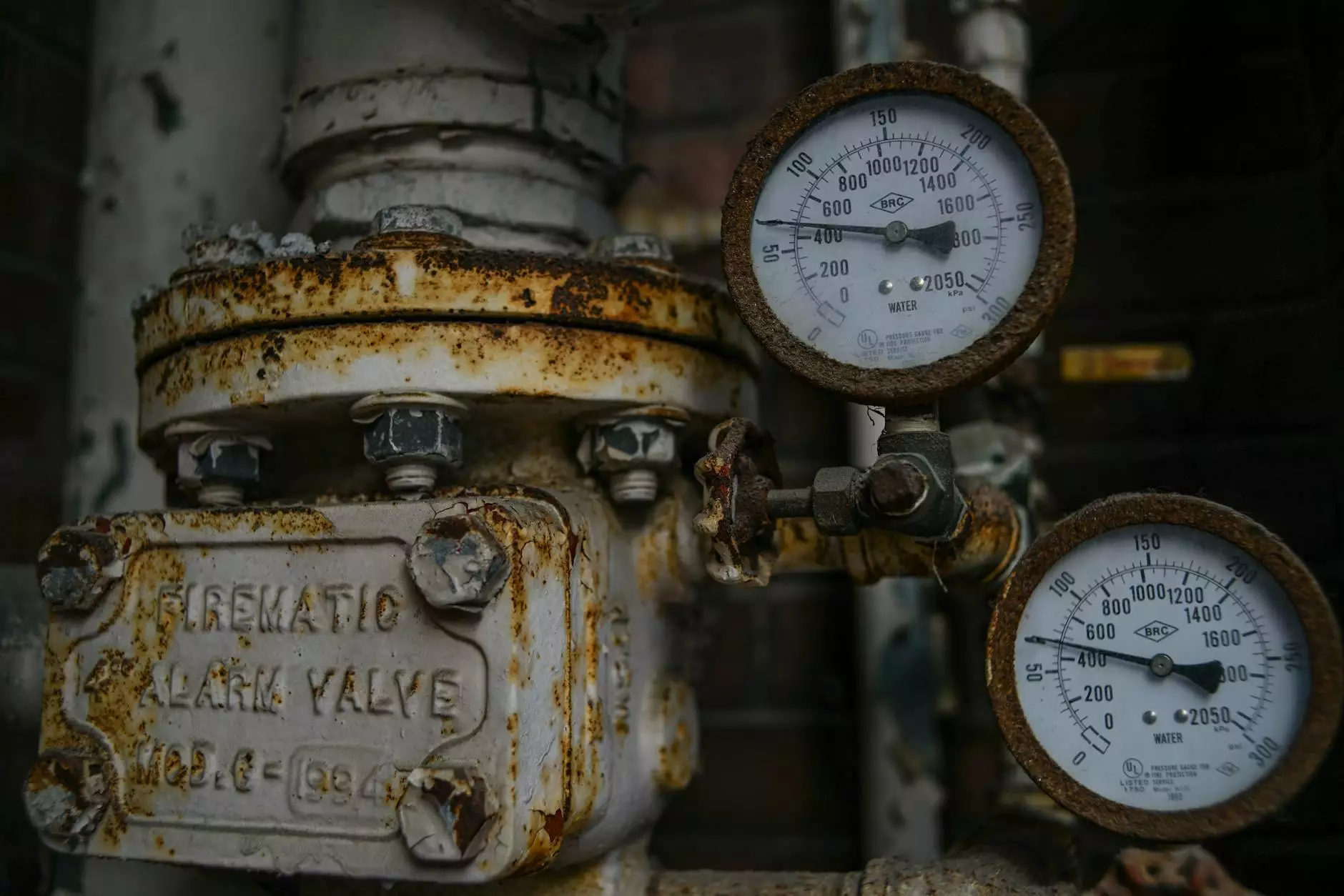

Conduct routine inspections of the solenoid valves for signs of wear, corrosion, or damage. Early identification of issues can prevent more significant problems down the line.

Cleaning

Keep solenoid valves clean from debris and contaminants. Regular cleaning can significantly enhance functionality and reduce the likelihood of blockages.

Check Electrical Connections

Inspect electrical connections regularly to ensure they're secure and free from corrosion. Loose or corroded connections can lead to erratic valve performance.

Timely Replacement

Understand the typical lifespan of your diesel solenoid valves, and proactively replace them to avoid unexpected failures.

Choosing the Right Diesel Solenoid Valve Supplier

Selecting the best supplier for your diesel solenoid valves is crucial. Here are some factors to consider:

Reputation and Reliability

Choose suppliers with a solid reputation in the industry. Look for reviews and testimonials that speak to their reliability and product quality.

Quality Assurance

Ensure that the supplier you choose adheres to strict quality control standards. Quality assurance processes are vital for ensuring the solenoid valves meet necessary performance and safety standards.

Product Range

A comprehensive product range allows you to source all necessary components from a single supplier, simplifying your procurement process.

After-Sales Service

Choose suppliers that offer excellent after-sales service, including technical support and replacement parts. This will be invaluable for maintaining your equipment.

Conclusion: The Future of Diesel Engines with Solenoid Valves

As we venture further into the era of advanced diesel technology, the role of diesel solenoid valves will only continue to grow in importance. Their ability to enhance performance, fuel efficiency, and reduce emissions makes them indispensable in modern diesel engines.

For those in the market for diesel engine parts or seeking reputable spare parts suppliers, consider exploring options available at client-diesel.com. With the right information and components, you can ensure your diesel engines run smoothly and effectively, meeting the demands of today’s industrial standards.

Investing in quality diesel solenoid valves will yield benefits not just in performance but also in operational costs and environmental sustainability. By understanding their functionality and importance, you position your business for greater success in the competitive world of diesel engine mechanics.